Complex Engineering

Have you seen how chemistry, physics, and engineering combine together to provide a secure and pleasurable drive. While tire models differ depending on the product and manufacturer, the usual wheel has above 100 constituents. Natural rubber, synthetic rubber, steel, nylon, silica (produced from sand), polyester, carbon black, petroleum, and other materials can be found in tires. Do you want to see how these materials look? Here is a video for you to enjoy the satisfying manufacturing of a tire through different components.

What Are the Different Components of a Tire?

Though rubber is the most widely used material in tires, there are a variety of others. Some tires include up to 200 differentiated raw elements that are mixed with rubber compounds to form the individual components of the tire's structure.

Compounding of Rubber

Rubber mixing is similar to making a cake batter. Different substances are combined to create compounds with distinct properties. The outsole substance on the outside gives momentum and mileage, while the rubber on the inside of the tire binds to the belt system. It provides tread area safety. Because of the various materials utilised in the tire, rubber compositions may vary.

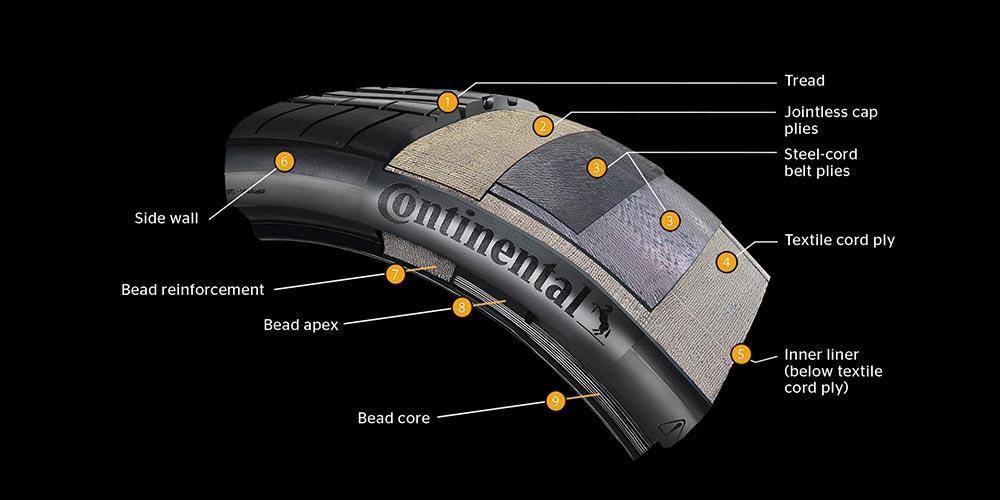

Components of Tires

Each tire producer selects materials with distinct technologies in mind. Whilst interacting with the other factors, each tire component is designed to deliver benefits particular to its purpose.

Structure of Tires

In the tempering process, tire components are joined like a puzzle and moulded together, causing the tire components and rubber compounds to attach to their surrounding components, resulting in a single product. The major purpose of the belt system is to provide stability to the tread area of the tire, which helps with wear, handling, and adherence. To produce traction and handling capabilities, the belt system works in tandem with the tire's sidewall and tread.

Casing for tires

The tire casing, which contains the bead, sidewall, body ply, and inner liner, is to be the tire's main body. Excluding the Tread and Belt System.

The Ply of the Body

The majority of passenger tire cases are multi-ply, with polyester, nylon, or rayon strands woven into the rubber compound. The enclosing rubber is strengthened by these strands. Polyester is widely utilised since it offers outstanding rubber adhesive, high strength, and decent riding qualities at a low weight, as well as heat removal properties. Nylon and rayon are two more fabric materials utilised in tire casings, each with somewhat various benefits tailored to specific tire conditions.

The Surrounding Area

The tire's sidewall is made of a distinct rubber mix that adds flexibility and weather resistance into a tire. Steel and/or nylon inclusions may be used in some tires, such as performance tires, to give faster driving experience.

The Bead

Tire bead bundles keep the tire firmly attached to the wheel. Massive steel strands are coiled with each other to produce a wire or ribbon-like structure. To keep the beaded bunches in position, the covering sheets are wrapped over them. A rubber constituent bead filler is integrated into the bead structure and stretches into the sidewall region. The outer bead rubber compound is generally a robust, resilient composition that can resist the rigours of fastening the tire to the wheel.

The Innerliner

As an air seal inside the tire, a special rubber composition is used. This inner liner layer is comparable to an inner tube in that it lacks cord reinforcement.

The Belt System

During the building process, the belt system is installed on top of the casing. The primary role of the belt system is to offer steadiness to the tire's surface area, which helps with wearing, control, and grip. Steel is the most often used belt component. Steel belts offer sturdiness to the tread region without increasing much to the tire's volume. The belt system is typically made up of two layers of steel cable positioned at opposite angles. Two stacked piles of steel cable are the most typical belt arrangement.

The Tread

During the production process, the tread slab is mounted on top of the belt system. Tread is typically made up of two rubber compounds: tread bottom and tread cap. When the tire is cured, the tread base compounds bond to the belt system, boosting endurance and stabilising the layers of polyester cords, known as plies, that make up the under tread. Tread caps are often constructed of a surface roughness, elevated rubber compound that interacts with the tread base and tread pattern to offer traction and mileage. The tread pattern of the tire is moulded into the tread cap rubber during the curing process.

Construction of passenger tires vs. light truck tires

The structure of a passenger tire and a light truck tire differs due to their functions and operating circumstances. Light truck tires are meant to function in harsh situations, typically lifting heavier loads and travelling off-road. Light truck tires may feature an extra casing ply, an added belt, a stronger belt steel cable, and/or a wider bead with more sidewall rubber, which is why they are heavier than passenger tires. Light truck tires often have better weight bearing capacity.